Can Your Cleanroom Flooring Maintain ISO 14644-1 Compliance After 10 Years?

The materials used in cleanroom design are essential to ensuring compliance with regulatory standards and maintaining the stability of production parameters. Cleanroom flooring is particularly important, as it plays a key role in maintaining a controlled environment. Choosing the right flooring materials is crucial to meet cleanroom classification requirements, such as GMP and ISO standards, and to ensure long-term performance.

Cleanroom flooring requirements

Biocontamination control ISO 846

In cleanrooms, particularly in the pharmaceutical industry, controlling biocontamination is essential to prevent the proliferation of microorganisms like bacteria and fungi. Materials used in these environments, including cleanroom flooring, must not promote the growth of any form of biocontamination.

Clean room flooring should be certified by a third-party laboratory according to ISO 846 standards. This certification evaluates bacterial and fungal growth (measured in colony-forming units, or CFUs) on the flooring surface over a 28-day period. Flooring compliant with this standard must demonstrate zero bacterial or fungal growth during the test, ensuring its suitability for controlled environments.

Particular decontamination ISO 4628-1 &-2

Approximately 70% of residual airborne particles settle on the floor after air treatment in cleanrooms. To prevent contamination risks, flooring clean room solutions must be designed for easy cleaning and effective particle removal.

To ensure compliance, the flooring’s surface should leave no residual particles after cleaning. Testing, such as the Riboflavin test conducted under ISO 4628-1 and -2 standards by third-party laboratories, verifies that the flooring's top layer can be thoroughly decontaminated. This guarantees the cleanroom floor tiles can maintain a particle-free surface, supporting optimal cleanliness and reducing biocontamination risks.

Resistance and durability

Throughout its lifespan, cleanroom flooring is subjected to various challenges, including high pedestrian or mechanical traffic, impacts, scratches, chemical exposure, and frequent cleaning with aggressive decontamination products such as hydrogen peroxide (H₂O₂). To ensure long-term performance, it is crucial to identify the specific constraints the flooring will face and select a solution designed to withstand these conditions. Cleanroom flooring must be resilient enough to maintain compliance and functionality even under rigorous use.

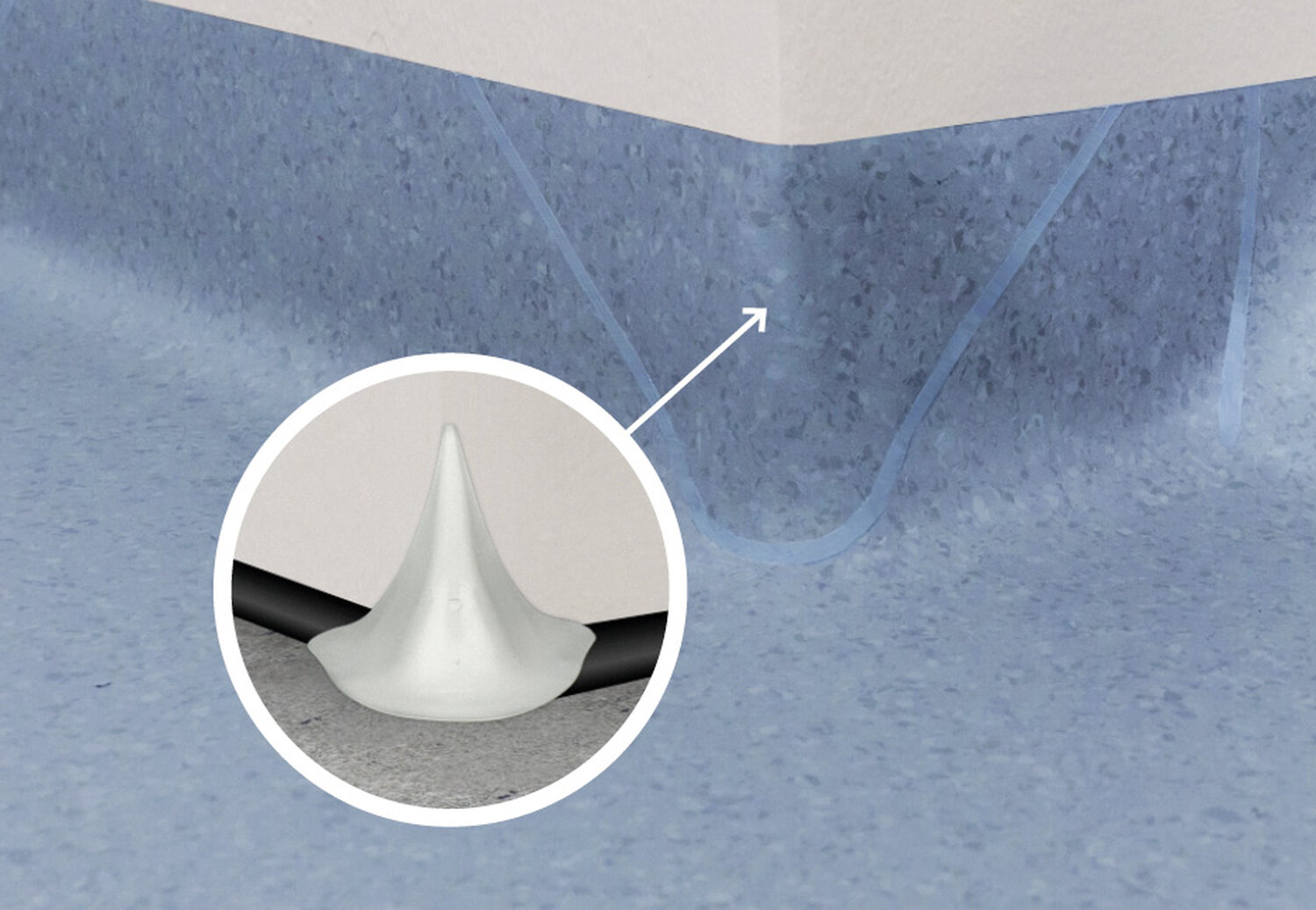

Watertightness

Watertight flooring is vital for maintaining a clean and controlled environment. Proper installation ensures seamless connections between rolls through hot welding and secure floor-to-wall joints using coving systems. Advanced systems, like the Watertightness Control System (WCS), allow for immediate and ongoing verification of your flooring's watertightness. These systems can detect weaknesses, such as impacts or deep cuts, that may compromise the floor’s integrity but are invisible to the naked eye. Early detection ensures timely repairs, preserving the flooring's performance over time.

Maintenance / Repairs

Flooring repairs in controlled environments, whether during operation or at rest, require efficient and minimally disruptive solutions. Unlike epoxy or polyurethane resin flooring, vinyl flooring allows for quick and easy repairs. Small damages, such as cuts or impacts, can be resolved through hot welding, and sections of flooring can be replaced without the need to shut down production. This makes vinyl an ideal choice for cleanroom environments where uninterrupted operations are a priority.

ESD properties

In cleanrooms used by industries like pharmaceuticals or electronics, installing ESD (Electrostatic Discharge) flooring is often necessary to prevent potential risks. ESD flooring mitigates the dangers of electrostatic discharge, which could harm sensitive products such as semiconductors or printed circuit boards, disrupt processes involving machinery or electronics, or endanger people by increasing the risk of fire or explosion in ATEX areas.

To address specific ESD concerns, it is crucial to select flooring that meets the appropriate ESD standard, such as IEC 61340, ANSI S20.20, or EN14041. Choosing the correct flooring ensures compliance and protection for both the environment and the equipment within it.

The Mipolam Biocontrol Clean, the only solution guaranteed ISO 14644-1 over several years in use

Cleanroom flooring is typically tested by independent laboratories when newly installed to evaluate particle release levels. However, after years of wear and tear caused by traffic and regular use, particle emissions can increase significantly, potentially leading to non-compliance with cleanroom standards. To ensure long-term performance, flooring selection must account for durability and aging to maintain compliance with ISO 14644-1 requirements.

Contact our cleanroom flooring experts

Get in touch with our cleanrooms experts for information and advice on Gerflor's custom cleanroom solutions.

Thank you for your request

Our Industry experts will contact you soon to go through your request.

About Gerflor

For over 80 years, Gerflor has been a global leader in crafting, producing, promoting, and distributing cutting-edge, environmentally responsible flooring solutions. Our extensive product line caters to commercial healthcare, education, sports, and industry spaces. Committed to sustainability and top-notch quality, Gerflor provides flooring options that cater to the diverse demands of customers worldwide. Our focus on creating spaces that inspire, enhance well-being, boost performance, and deliver a measurable return on investment underscores our dedication to customer satisfaction and environmental responsibility. Choose Gerflor for flooring solutions that elevate spaces and stand the test of time.